Recycling

How recycled paper is made

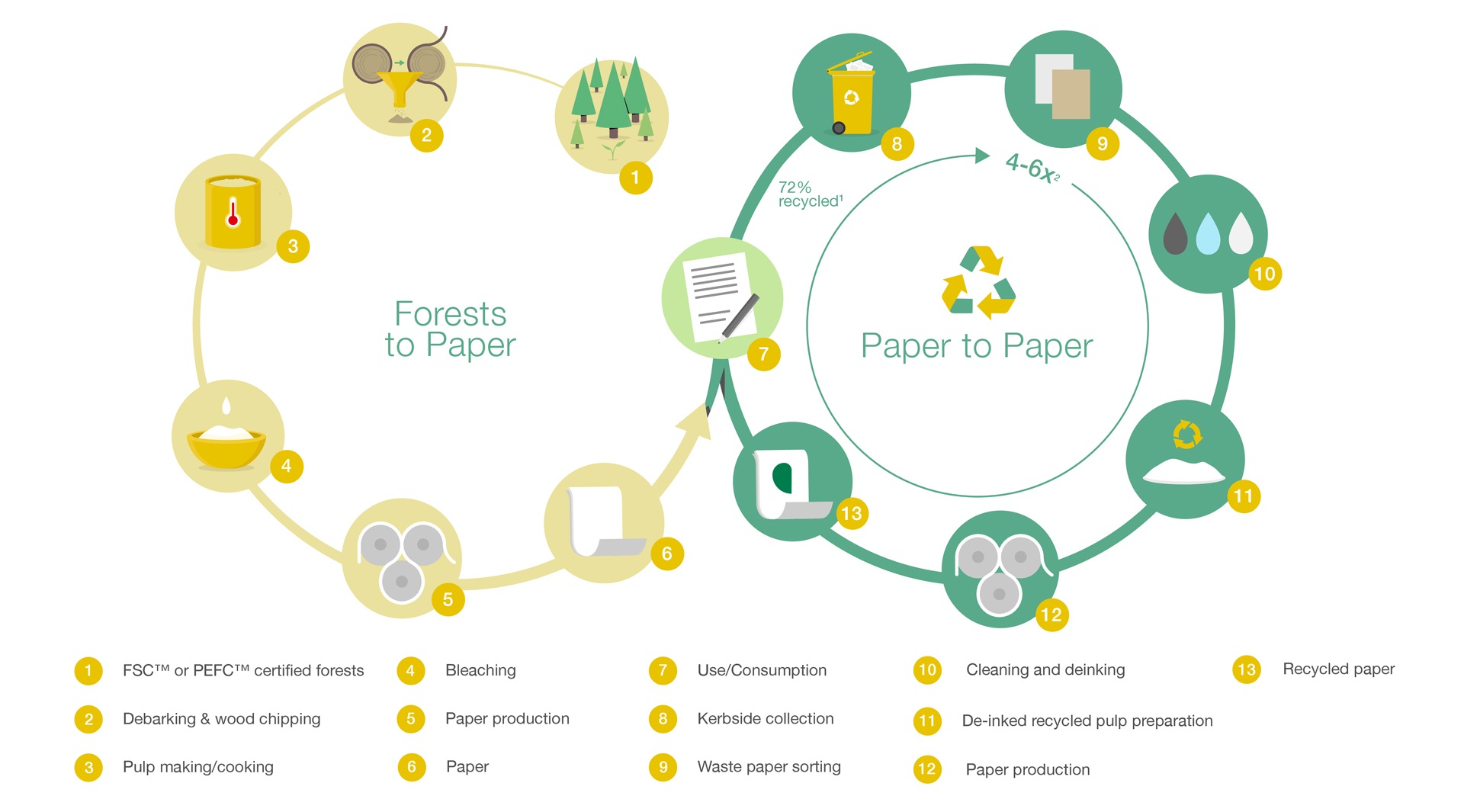

Recycled paper is a great way to contribute to a circular economy, as it has never been more important to use our natural resources consciously. The paper recycling process involves a complex network of post-consumer waste collection, cleaning, deinking and finally, the production of new paper from what was formerly waste. Let us guide you through the process of making our high-quality NAUTILUS® recycled papers.

Collecting and sorting: not all wastepaper is the same

Office paper is a very small part of all wastepaper that is collected. Mostly, it consists of discarded packaging, typically made of brown/kraft paper. Collected wastepaper is therefore sorted into different grades to be recycled appropriately. The grade of the papers is, among other specifications, determined by the length of the fibres, which shorten each time they undergo the recycling process.

To create high-quality recycled papers like our NAUTILUS® range, we need white wastepaper such as discarded office paper, as it is simply not possible to produce high-quality office and professional printing papers from old newspapers or packaging. Hygiene paper and carrier bags, on the other hand, can be produced from lower wastepaper grades.

Once the wastepaper has been collected and properly sorted, it can move on to its next destination. In our case, the white wastepaper goes to a pulp mill, where it can be cleaned up and de-inked.

Deinking and recycling paper

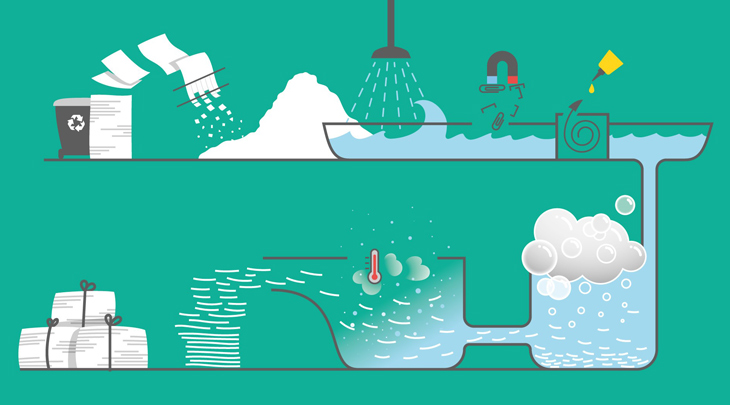

In their pulp mill in France, WEPA receives the sorted wastepaper, which is shredded and added to water – this is called a pulp suspension. This suspension goes through a series of filtering and deinking stages, to remove all printed ink from the fibres, so they can be reused.

This deinked pulp (DIP) is used to produce new paper, in a process identical to the one used to create paper made from fresh fibres. In a nutshell, in our Mondi Neusiedler mill in Lower Austria, the pulp is fed into the paper machine, water is added, and it is stretched, pressed, and dried. It takes roughly 1.4 tonnes of wastepaper to create 1 tonne of recycled paper.

Sourcing deinked pulp with WEPA

Among other suppliers, we source deinked pulp (DIP) from WEPA, who is a market leader in recycled hygiene paper. Additionally, they provide deinked pulp (DIP) to companies, like Mondi, who use it to create high-quality recycled papers, like NAUTILUS®. Through their experience and technical know-how, we are guaranteed the best quality for our production.

It is very important to us to work with suppliers and partners who share our sustainability values, and WEPA does.

We aim to use raw materials with the best ecological performance based on the circular economy, because the fibres we use in our products have a decisive impact on the ecological footprint. We make sure to source our fibres locally wherever possible, meaning that most of the fibres are sourced within a 300 km radius of our production sites. Our wastepaper processing facilities are mainly in France, Benelux and Germany.

— Laurent Benault, Plant Manager WEPA Greenfield

New challenges on the horizon: a shortage of paper to recycle

One of the main problems we face nowadays, however, isn’t the technical know-how and expertise to recycle paper, but rather the availability of recovered paper. The shift from printed materials to digital communication and the impact of the pandemic resulting in more employees working from home and consequently less office printing, are both big contributing factors to the scarcity of high-quality white wastepaper.

When we consider the cycle of sustainability, fresh fibre paper is necessary to keep the cycle going. This is because some papers like sanitary paper cannot be recycled, and papers that can be recycled can’t be recycled infinitely, as eventually the fibres become too short to be repurposed.

Since the goal is to keep those fibres in circulation for as long as possible, it is crucial to consider how paper is made in the first place — what chemicals go into it, and how well it can be recycled, or composted.

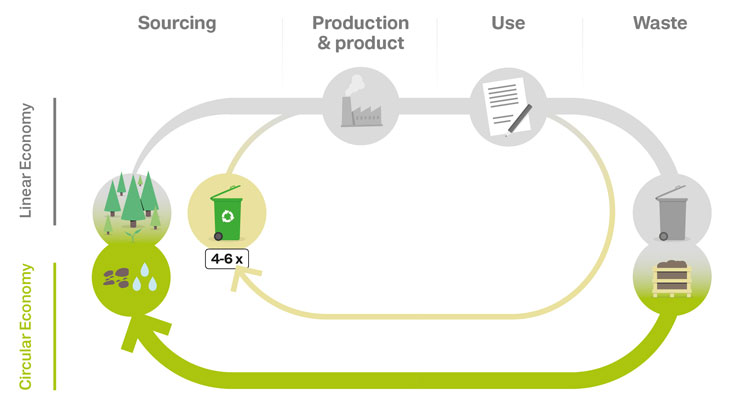

The big picture: recycling is only one part of sustainable design

Sustainable design considers the bigger picture, and sustainability should be synonymous with circularity. We need to shift from the mentality that recycled papers are the only sustainable choice, and instead design all products to be safely returned to the environment once they have fulfilled their lifecycle, without causing harm to people and nature, for a truly circular approach.

That is why our extensive portfolio of uncoated fine papers from our Mondi Neusiedler and Mondi SCP mills, in Austria and Slovakia respectively, are

Cradle to Cradle Certified® at the Bronze level*. The Cradle to Cradle Certified® Products Program is the most advanced global standard for safe, circular and responsible materials and products. Reaching the Bronze level from the Cradle to Cradle Certified® Products Program shows that our products have been externally verified to meet the high standards and demanding requirements of this certification.

Paper recycling: in a nutshell

Paper recycling follows a well-established process of collecting, sorting and deinking. The separation of wastepaper into assorted grades means that different types of paper can be repurposed into new products, maximising the use of our natural resources. This also ensures that fibres are repurposed into the highest quality possible for their new recycled purpose.

One of the biggest challenges in the paper recycling process is a shortage of raw materials due to the availability of high-quality recovered paper steadily decreasing. Since paper cannot be infinitely recycled, fresh fibres remain essential to maintain the cycle of paper production.

* Cradle to Cradle Certified® is a registered trademark of the Cradle to Cradle Products Innovation Institute.