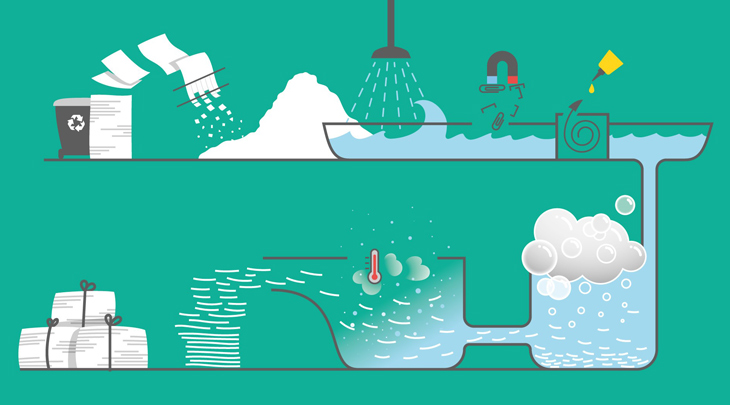

This process includes the initial pulping of the paper, turning it into what is referred to as a slurry. Afterwards, this slurry goes through a series of filtering and cleaning stages. One of those stages is called flotation de-inking, because by adding a collector agent and then blowing air into the pulp-filled drum, the colour- or ink-particles float to the surface, while the pulp drops to the bottom. This step is repeated until the bubbles floating to the surface are clear, with all the ink finally removed from the slurry. What needs to be noted here is, that during the whole process, no chlorine to bleach the pulp is used. It’s what’s commonly referred to as PCF, process chlorine free.

Finally, it is run through a dispersion system, ridding it of remaining dirt spots.

What remains now is so-called DIP, short for de-inked pulp.

Recycling

When old becomes new again

Recycled paper comes in all shapes and forms, but until we get there, a lot of things have to happen.

But what exactly happens with the waste paper we put into those boxes? How is this mix of copy paper, packaging material or cardboard turned into recycled products like Mondi's NAUTILUS® paper?

Regardless of whether it's a communal or a private sorting site, the next step is the same everywhere: the waste paper is sorted into its different grades. These grades, standardised by the European Committee for Standardisation, are split into five different groups, from ordinary to special grades. NAUTILUS, by the way, is made of 100% post-consumer waste, meaning it is not trimmings or other waste from paper production, but rather paper that was used by end-consumers.

It's important to note that when sending wastepaper to be recycled, it should be free of any kinds of non-paper components. Metal, plastic, glass, textiles, sand or synthetic materials all make the sorting of wastepaper more difficult, sometimes even hazardous and generally make the whole recycling process more costly.

Among the above mentioned grades, only a small number is usable to produce the kind of pulp we need for NAUTILUS®.

Once the wastepaper suitable for the production of NAUTILUS is collected, it needs to be cleaned up, a process that is known as de-inking.

Infobox

Learn more

By the way, and you were probably wondering that already, it takes roughly 1.4 tonnes of waste paper to get 1 tonne of recycled paper.

In the end, those containers filled with discarded paper materials have been turned into fresh reams of NAUTILUS recycled paper, completing one part of the Cycle of Sustainability. But that's another story (literally, you can read it here).