The deinkability of a printed product is determined by three main factors: the printing method and the type of ink used, the paper it is printed on, and the deinking method that is used. This story will predominantly focus on the printing technology and type of ink used, but let’s quickly address the deinking method.

Paper deinking: which inks are most suitable for deinking?

One of the most complex steps in the paper recycling process is deinking, in other words, removing printed ink from used paper, so it can be turned into new paper. This process is detailed in part one of our series, which you can read here. One of the main challenges of deinking is that inks aren’t all the same. While some may be easy to remove, others may prove more stubborn — or perhaps even incompatible — with available deinking methods, which is what we will be tackling in this story.

The basics of deinking

The most common method of deinking is froth flotation, which works very well at removing conventional offset and illustration gravure inks. These printing technologies have been around the longest and make up the bulk of recovered paper, so this deinking process was specifically developed to remove these inks. The development of digital printing machines and newer printing technologies has meant that there are new types of inks on the market, which have proven tricky or even entirely incompatible to deink with this method.

You can read all about froth flotation deinking here, but in a nutshell, recovered wastepaper is collected, sorted, shredded, filtered, cleaned, and added to water to begin froth flotation deinking. In this process, a soapy solution is added to the mixture of paper fibres and water, and air is blown into the tank to form bubbles. The ink particles separate from the paper fibres, attach themselves to the soapy bubbles and float up to the top where a foam (or froth) is built up and skimmed off, leaving white deinked paper fibres behind.

What determines good deinkability?

The deinkability of inks is determined by several factors, but the most important are whether the inks are water-shy or water-soluble, the size of the ink particles and characteristics of the ink particles.

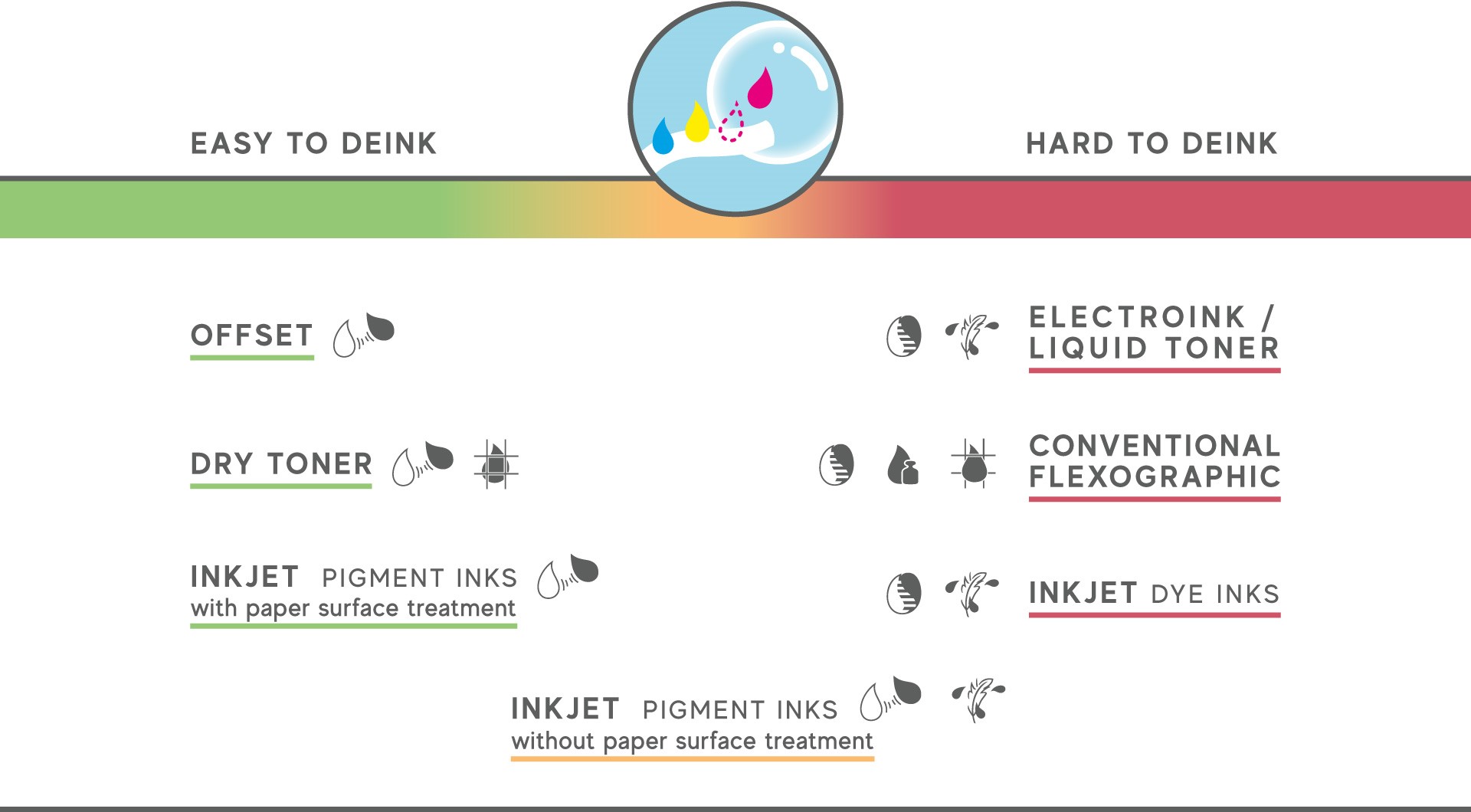

The graph below shows how suitable or unsuitable different types of inks are when it comes to deinking.

Water-shy or water-soluble

The process of froth flotation deinking works by separating hydrophobic materials — molecules repelled by water or water-shy — from hydrophilic ones — molecules attracted to water or water-soluble.

As the paper fibres swell up in the soapy water, water-shy ink particles detach from the fibres and look for another medium to bond to, happily attaching themselves to the froth flotation soap bubbles. Water-soluble ink particles, however, though theoretically easy to separate from the paper fibres, are attracted to water. Because of this, the ink particles end up mixing into the water source (and colouring it), rather than attaching to the soapy bubbles.

Think of water-soluble inks like a red sock in the washing machine — small amounts are enough to dye the whole wash pink. Unlike a washing machine, however, froth flotation deinking uses a closed water cycle. This means that rather than having to change the water every time, the water used for deinking is not released directly back into the environment but is reused in the next cycle. Although this is great news in terms of sustainability, the downside is that in such a closed cycle, inks that cannot be removed from the water naturally accumulate with time, meaning that every red sock that comes into the process colours the water cycle.

Because of this, water-based inks — which are water-soluble by nature — cannot be effectively removed during froth flotation deinking and instead accumulate in its closed water system.

Size matters

Particle size also has a big impact on deinkability, because it affects the way the ink particles behave in the froth flotation deinking method. The Goldilocks principle is a good way of looking at ink particle size — too small and they cannot properly attach to the soap bubbles and be carried to the surface; too large and their weight will make them sink to the bottom; but somewhere in the middle, is the optimal size that makes them just right. The exact range that makes them ‘just right’ varies depending on the specific type of ink used and the conditions of the flotation process.

Particle characteristics (stiff versus flexible)

The froth flotation process is repeated in several chambers to ensure the best possible quality of deinked paper fibres. As mentioned, froth flotation works within a closed water cycle. This means that the paper fibres travel through each chamber with the same water from start to finish. Between each chamber is a mesh screen to help catch any stubborn particles. Here, the characteristics of the ink particles make all the difference. There are ‘stiff’ particles, which are easily caught by this screen, and ‘flexible’ particles that can get through the screen due to their flexibility.

Dry toner particles, for example, contain a stiff polyester, which is caught by the screen. Liquid toner particles, on the other hand, contain a flexible polyethylene (PE) that passes straight through the screen.

In conclusion: deinking is a complex undertaking

As is evident, deinking is a complex topic. Inks fall on a spectrum, and they are most certainly not black and white. Although there are guidelines for which inks work best with froth flotation deinking, there are always exceptions, and certain inks need to be assessed on a case-by-case basis, to identify whether certain factors — like printing on a special paper — influence their deinkability.

You might be asking yourself why the process of deinking hasn’t evolved over time, or why this isn’t a more pressing matter in terms of our recycling systems being “polluted” with incompatible printing technologies. Traditional deinking plants were developed to cater to conventional offset and illustration gravure inks, and still today, most recovered paper is printed using these inks. Comparatively, digital prints only account for up to 3,85% of the total printed volume globally. In this figure, 2,4% are inkjet prints and 1,45% are electrophotography (toner) prints*. Though the amount of inkjet prints is expected to increase by 2027, this is still a very small piece of the overall pie.

So, although it only takes one red sock to dye the whole wash pink, when the whole basket is filled with whites, you prioritise washing whites. The odd red sock can be added to the darks, or in the case of paper, be recycled with other lower-grade materials, to create new products like kraft paper or corrugated materials.

*Figures taken from “The Future of Digital vs Offset Printing to 2027” by Jon Harper Smith

Published by © Smithers Information Ltd 2022

Explore the different ink types below and learn about their deinkability properties

To get a better understanding for the nuances between different ink types, select the different ink types below to learn whether they are suitable for deinking or not.

No, conventional flexographic inks are not deinkable using the froth flotation method.

Water-based inks are typically used in flexographic printing, and these cannot be fully removed in froth flotation deinking. The slightly alkaline condition of the deinking process leads the binding agent in the ink to decompose, resulting in miniscule water-soluble pigment particles, smaller than 1 micron. Such particles are too small to adhere to air bubbles and allow for good flotation. This, combined with the fact that the particles are water-soluble, means that the ink particles move through the froth flotation process together with the paper fibres. As a result, the water turns grey over time, as does the final deinked pulp. Even small amounts of flexographic printed materials present in a mixture are enough to drastically deteriorate the quality and whiteness of the deinked pulp.

It’s more complicated than a simple yes or no.

Inkjet inks are used in professional and office printers. They are mostly water-based and contained in cartridges comprised of a certain pigment to water ratio (which keeps the ink a liquid), as well as additional ingredients like glycol or glycerine. These additional components allow the ink to penetrate the paper and stay there — when it comes to deinking, however, this makes it difficult to separate the ink from the paper fibres. Papers like our DNS high-speed inkjet NF have a surface treatment that creates an ‘ink acceptance layer’ to keep the pigments on the surface of the paper. Using these specially treated papers significantly improves the deinkability of a printed product.

Let’s look more closely at the two categories of inkjet inks: dye-based and pigment-based.

Dye-based inkjet inks

Dye-based inkjet inks are not deinkable using the froth flotation method.

Dye-based inkjet inks are predominantly used in home desktop inkjet printers. These inks are made up of colourant that is fully dissolved in water. During froth flotation deinking, dye-based inkjet inks act like the ‘red sock in the washing machine’.

In addition to being too small to effectively adhere to the soap bubbles, the ink particles are water-soluble, and therefore end up mixing into and colouring the water cycle.

Pigment-based inkjet inks

Pigment-based inkjet inks are easier to remove using the froth flotation method, but still not optimal. To improve deinkability, use a specially treated paper.

Pigment-based inkjet inks are most commonly used in high-speed inkjet printers. These inks are water-shy and have slightly larger ink particles than their dye-based counterparts. This allows the ink particles to adhere to the soapy bubbles more easily, but pigment-based inkjet inks are still hard to separate from the paper fibres. Using specially treated inkjet paper, like DNS high-speed inkjet NF and DNS high-speed inkjet CF, helps to circumvent this issue, because the surface treatment helps to separate the ink from the paper fibres.

Yes, dry toner is deinkable using the froth flotation method.

One of the most popular methods for everyday digital printing is dry toner laser printing and the good news is that it is optimal for froth flotation deinking. This printing technology doesn’t use a liquid ink to print, but rather a very fine powder called toner. This dry toner is contained in cartridges, and it is deposited on the paper using laser technology, after which the paper runs through a fuser, which uses heat to fuse the pigment in place.

Unlike most other types of ink, dry toner does not contain any liquid. Because no solvent is present, the dry toner stays on the surface of the paper, rather than seeping into the fibres. During froth flotation deinking, the ink particles have the ideal size to attach to the soapy bubbles. Additional components present in dry toner, like polyester resin and wax, are thermally melted during the printing/fusing process. When it comes to deinking, these ‘stiff’ particles are easily caught by the filter screens and do not affect the outcome.

No, Electroink / liquid toner is not deinkable using the froth flotation method.

Electroink is a type of liquid toner developed by HP Indigo that consists of electrically charged pigment particles dissolved in a transfer liquid. This ink creates high-quality prints that are fade-resistant, rub-resistant, and allow for glossy printing, making it a popular printing method for, for example, photos. The downside is that they are not suitable for froth flotation deinking.

The dissolvers used in froth flotation deinking plants (the soapy solution) are not powerful enough to break down the liquid toner particles, and the very large clusters of Electroink particles are too heavy to adhere to the soapy bubbles.

Additionally, liquid toner contains an elastic polyethylene (PE) film, which cannot be removed sufficiently. These ‘flexible’ particles pass straight through the filter screens, dirtying the water.

It’s more complicated than a simple yes or no.

Ultraviolet curing (or UV curing) is a photochemical process in which high-intensity ultraviolet light is used to instantly cure or “dry” inks, coatings, or adhesives. UV-cured inks are designed to be resistant to water and solvents, which can also make them resistant to traditional deinking methods. Additionally, some specialty inks like metallic or fluorescent inks may contain heavy metals or other substances that make them difficult to remove during deinking and may leave behind residue or stains on the paper.

Traditionally, UV-cured inks have been considered bad for deinking because they leave dirt spots in the deinked pulp (DIP). In recent years, some ink manufacturers have developed special deinkable UV inks. These special inks are still the exception rather than the rule. So, unless explicitly stated, UV inks and LE-UV inks are not considered deinkable. This is especially true if a varnish is applied on the print, as varnishes could affect the overall deinkability.