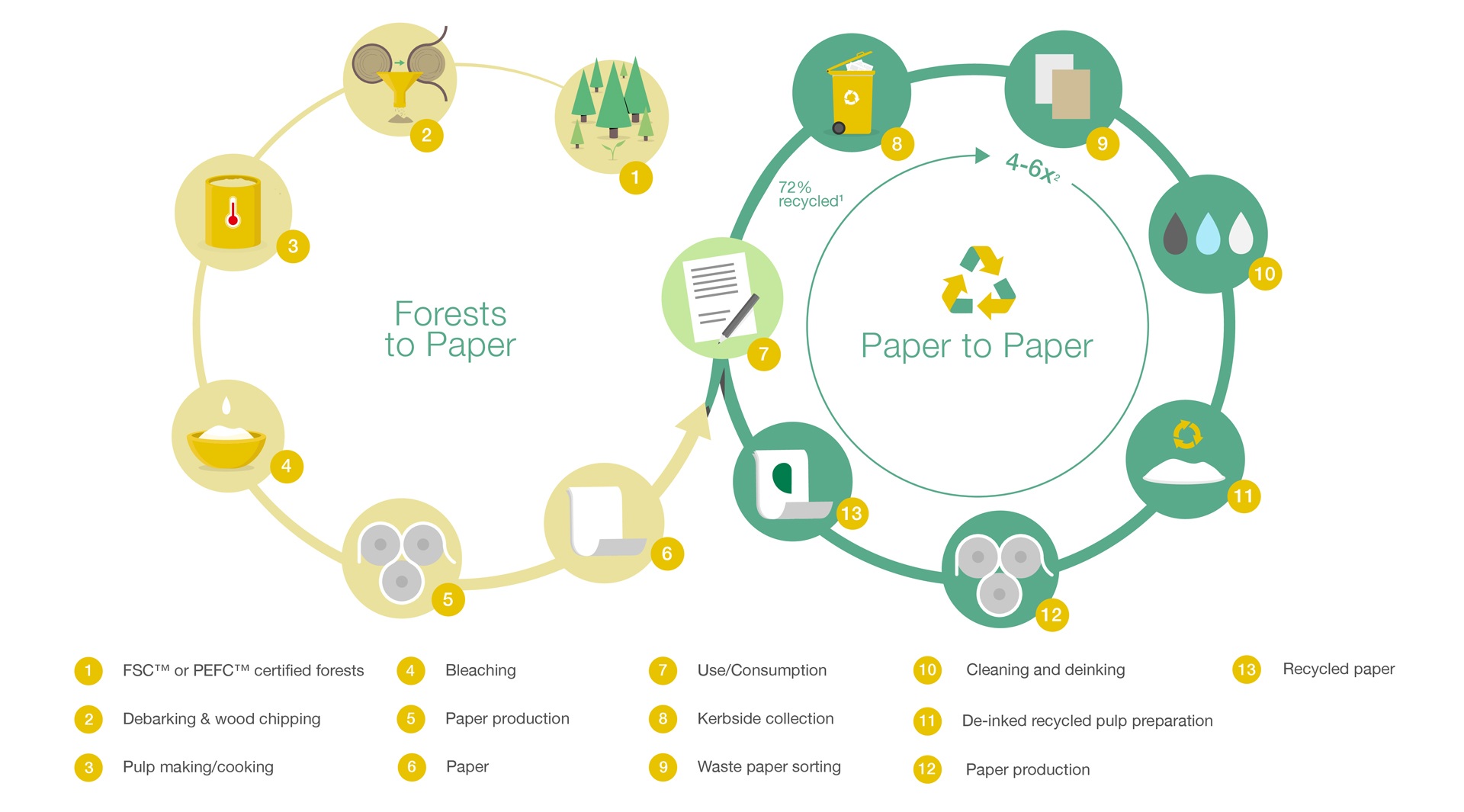

As the illustration shows, this is the first part of a cycle that always ends in the production of recycled paper. Sometimes referred to as a circular economy, we like the image of a cycle of sustainability. Without fresh fibre, we'd eventually run out of recycled paper, and what better way to ensure constant supply of material for recycled paper than through sustainably produced paper from fresh fibre.

Unlike traditional producers of recycled paper, Mondi is in the fortunate position to be able to cover every aspect of the cycle of sustainability. Apart from the mill in the Liptov region, Mondi operates a number of mills all over Europe, which all use pulp from sustainably managed forests exclusively, either from Mondi-managed forests or bought from the world-market.

Both our forest to paper and our paper to paper approaches make the most of our resources. This allows us to not only produce Nautilus to the standards customers expect from paper made from fresh fibre, but also guarantees an unbroken supply chain. Today, tomorrow and the day after.

In short, our cycle of sustainability makes sure that Nautilus is made to last. Just like the deep forests of the Liptov region.

Recycling

Mondi and the cycle of sustainability

The possibility to create high-quality paper from a waste-product is a great thing. However, paper cannot be recycled indefinitely.

It's the year 2019 and recent months have made clear that there is one topic that will keep occupying our attention for years to come: the climate crisis. Floods, droughts, and various other weather phenomena are harbingers of what's to come, if a global rethinking of current energy consumption doesn't happen soon. That is a fact, one that has been urgently communicated by the vast majority of climate scientists.

It may sound like a doomsday scenario, but if we act now, it won't be. We can all do our part to mitigate the impact of an ever-warmer climate. In Mondi's case, it is not merely our commitment to sustainability and the reduction of our CO2-footprint, but also our commitment to producing Nautilus, our own brand of recycled paper.

Paper

Some notes on recycled paper

How do we get to recycled paper?

Looking at historical data, we can see how the use of recycled materials has gone up from 35% to 46% within a timespan of fifteen years, already eclipsing the use of fresh fibre. Meaning we are now using almost as much recycled paper as we do paper made from fresh fibre.

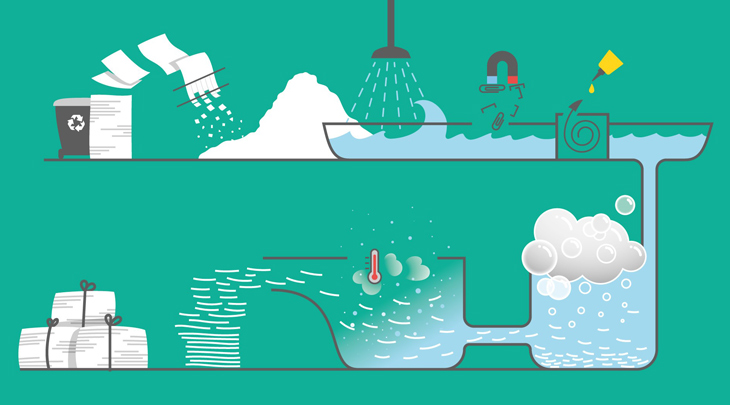

But how do we get to recycled paper in the first place?

At the beginning of the process is waste paper, usually collected kerbside. Post-consumer waste paper comes in all shapes, sizes and colours, so the obvious next step is a general sorting into paper that is fit for recycling and paper that isn't.

The next step demands an even closer look: what's the shade of the paper? How clean is it? When we choose paper that will ultimately be made into Nautilus, we make sure it’s of the best quality, in order to get the highest possible whiteness with as few dirt spots as possible.

But we're not quite there yet. Most post-consumer waste paper contains ink or similar materials, and we have to get rid of that. Cue the de-inking process, which, true to its name, removes the ink from the paper. What remains is a mixture that will, after a few more steps, be pulp fit for paper-making.

We're ready to produce Nautilus.

Cycle

The cycle of sustainability

Paper fibres last for four to six lifecycles

However, there's always a but: paper cannot be recycled indefinitely. At some point, the fibre will be too short, and usually that point comes after four to six lifecycles. That means that at some point, even with the most thorough post-consumer collection of waste paper, we would run out of usable paper to recycle.

This is where we return to the rolling hills and dense forests of the Liptov region. Here Mondi produces many of its paper brands, and the mill doing this is a so-called integrated mill: all the pulp used there is taken from sustainably grown forests of the region. The FSC™ or PEFC certified wood is taken from the forests to create so-called fresh fibre. This fibre is then turned into regular professional printing or office paper.

Infobox

Learn more

What’s the difference between pre- and post-consumer waste?

Nautilus is made entirely from post-consumer waste-paper. But, what really is the difference between post- and pre-consumer waste-paper? In a nutshell, pre-consumer waste-paper is any kind of waste collected before it had a chance to reach the consumer, like trimmings or clippings right at the factory. Post-consumer waste is paper that has been used by a consumer and has then been collected in a recycling effort.

Nautilus is made entirely from post-consumer waste-paper. But, what really is the difference between post- and pre-consumer waste-paper? In a nutshell, pre-consumer waste-paper is any kind of waste collected before it had a chance to reach the consumer, like trimmings or clippings right at the factory. Post-consumer waste is paper that has been used by a consumer and has then been collected in a recycling effort.

In this day and age, there’s a lot of talk about the sustainability of paper. TwoSides is an organization that informs and educates, dispelling myths about paper and providing the necessary facts to back up any claims. Have a look and see what preconceptions you might find challenged by their resources.

Click here to learn more – literally https://www.twosides.info/